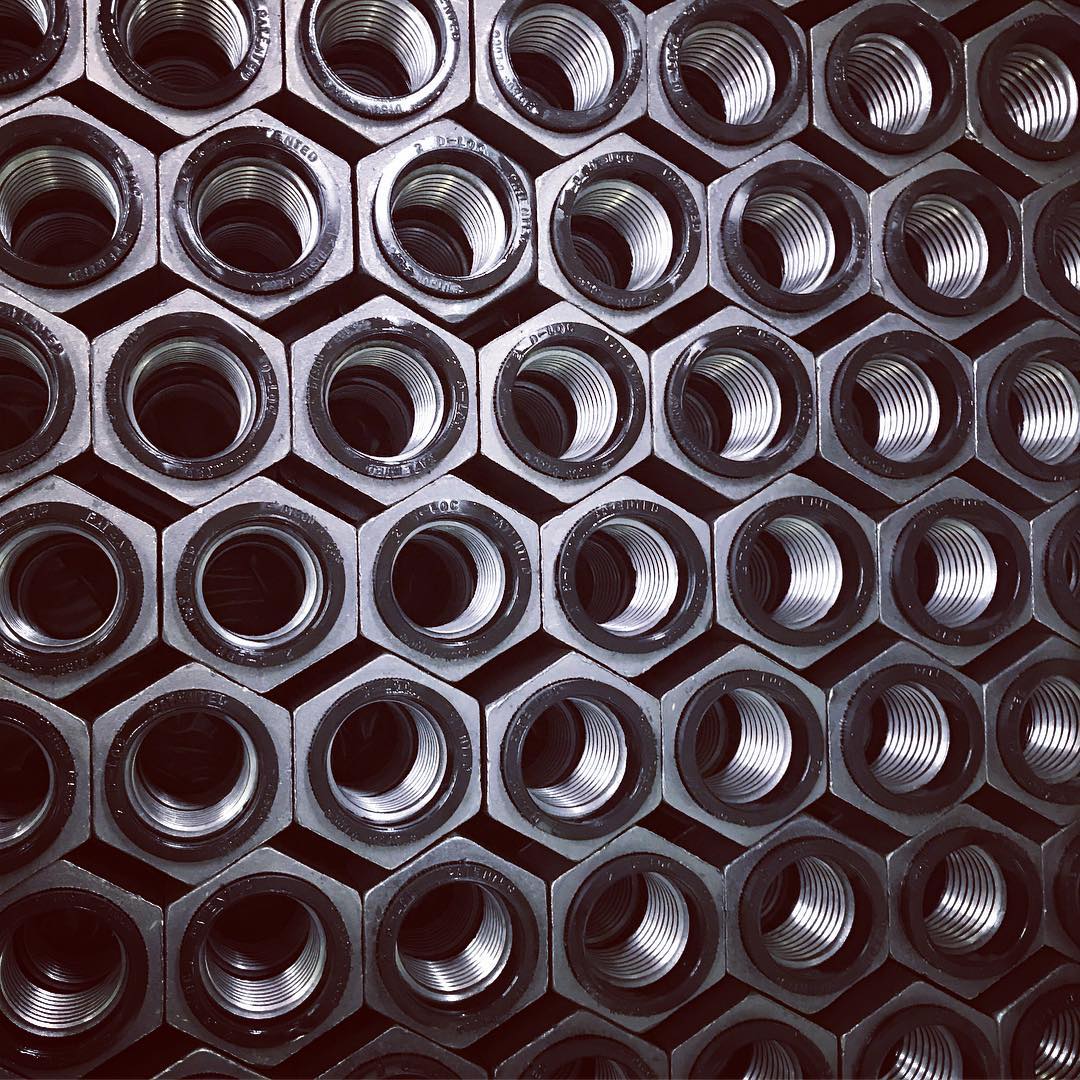

Dyson Corp., leading manufacture of 100% domestic large fasteners and forgings’ D-LOC lock and seal nuts are America’s leading solution for common vibration and liquid leackage problems typically present on the following applications: rod mills, ball mills, autogenous mills, crushers, shakers, overhead cranes, material handling equipment, presses, railway systems and mines.

Dyson is the patent holder of the original D-LOC and M-LOC free spinning lock and seal nuts, and is “the only manufacturer to produce D-LOC heavy hex nuts where complete thread engagement is achieved,” explains Patrick Linehan, Director of Engineering at Dyson Corp.

Linehan further clarifies, “This fully forged nut provides maximum strength and tension values for extreme working environments. D-LOC nuts distribute the bearing load on irregular surfaces and lock the bolt and nut assembly together. It also creates a water-tight seal. Vibration cannot loosen the assembly due to the locking element of this product.”

As the nut is torqued, the force expands the DY-LASTIC insert to form a tight plastic cushion on the bearing surface, on the nut, and between the threads of the bolt and nut. This reduces downtime and lowers maintenance and retorquing costs!

Learn more about the benefits of Dyson’s D-LOC lock nuts here.