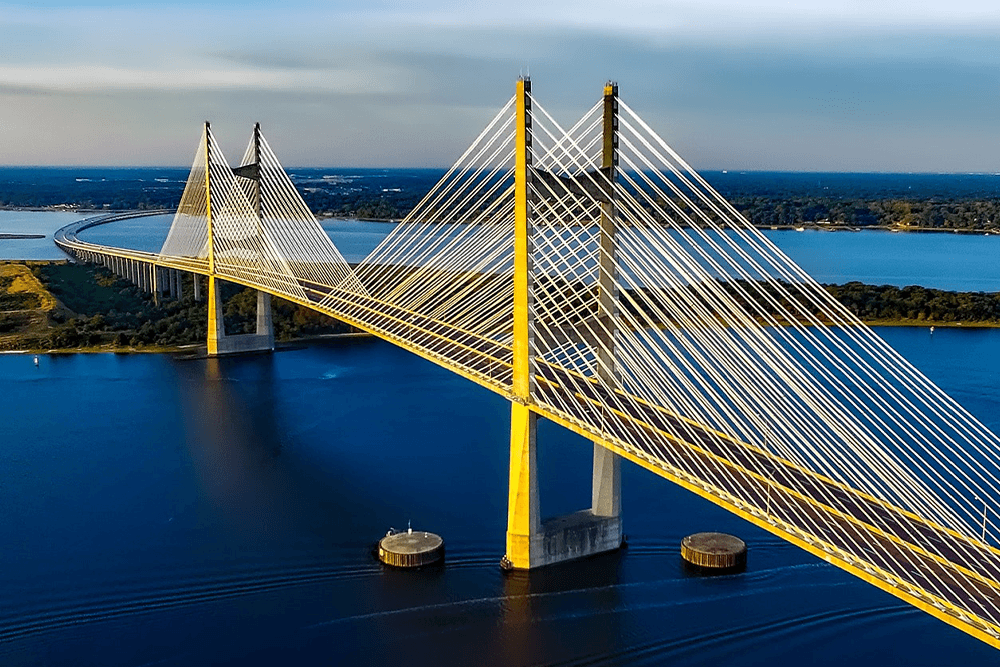

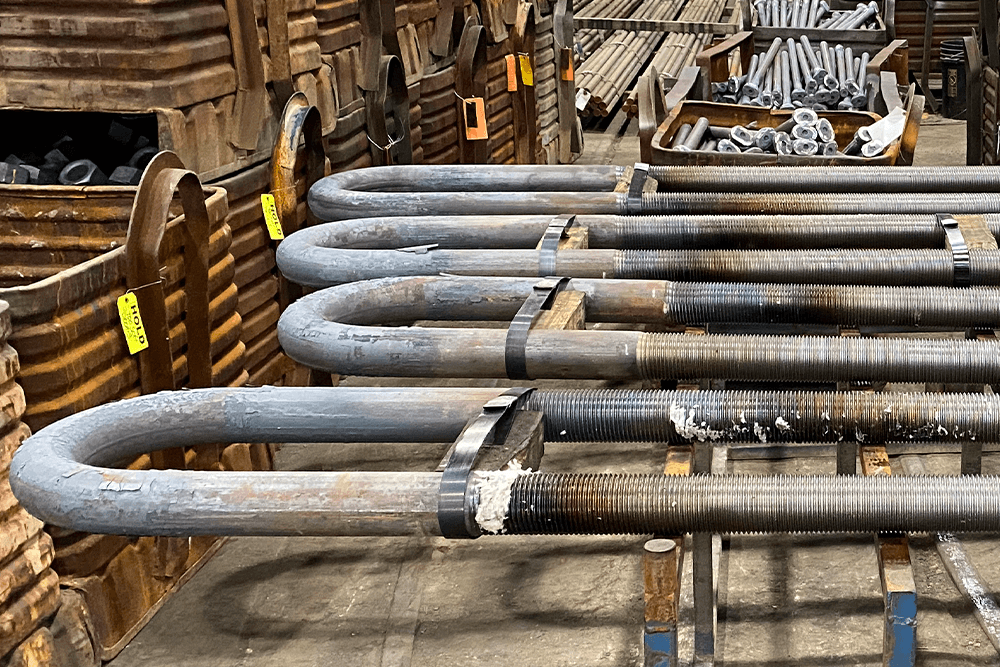

Rely on Our Stainless Steel Clevis Pins for Bridge Projects

So much detail-oriented work is required to create structurally-sound infrastructure such as a bridge. No detail is too small, all the way down to the quality of specialty fasteners used to hold sections of a bridge together. When users drive across massive bridges, they probably notice the concrete or the steel beams. However, they probably […]

Rely on Our Stainless Steel Clevis Pins for Bridge Projects Read More »