We Forge and Machine 100% American-Made Industrial Parts

Say goodbye to supply chain issues with Dyson Corp. All of our high-quality industrial parts and fasteners are crafted right here in the U.S. – from raw steel to finished product.

Our Industrial Products

Fasteners

We manufacture custom fasteners, heavy hex bolts, and numerous other bolts according to spec.

Domestic Nuts

We manufacture a variety of domestic heavy hex nuts, including our proprietary Dyson D-Loc™ nuts.

Anchor and Foundation Rods

Find anchor bolts, coil nuts, washers, PVC sleeves, and more built to spec.

Custom Forgings

We are your one-stop shop to forge any part in any material grade up to 10,000 lbs.

Machined Parts

We can manufacture custom machine parts in-house for your industrial machines.

What Does American-made Look Like?

Our products are 100% domestically manufactured from USA-poured or DFARS-compliant materials. We don’t use cheaper materials from other sources at any point in the manufacturing process. You can rest assured that your finished part was handled in the U.S. from start to finish.

Our D-Loc Nuts will Save You Time and Money

Dyson D-Loc™ nuts are manufactured to support liquid penetration and high vibration resistance. These nuts can be used for infrastructure and construction, oil and gas, and other high-strength structural applications.

Align with ESG Project Requirements

Are you required to procure products that meet ESG guidelines? We follow sustainable practices in manufacturing ESG compliant nuts (“green” nuts). Learn about our products.

Our Dedicated Services

Forging

Forging is what we do. Our forge shop has extensive capabilities that allow us to pass along savings to you.

Heat Treating

We use advanced technology and equipment to heat-treat a wide range of products in one location.

Machining

We perform turning, milling, drilling, tapping, and assembly in-house at our shop.

Thread Rolling

We use state-of-the-art machines to execute thread rolling with precision for every order.

Quality Inspection

We are ISO 9001:2015 Certified. We follow the strictest quality standards for your order.

Need To Get in Touch?

Our team is ready to help.

Industries We Serve

Wind Energy

Learn More

Locks and Dams

Learn More

Marine and Military

Learn More

Infrastructure and Construction

Learn More

Oil and Gas

Learn More

Mining

Learn More

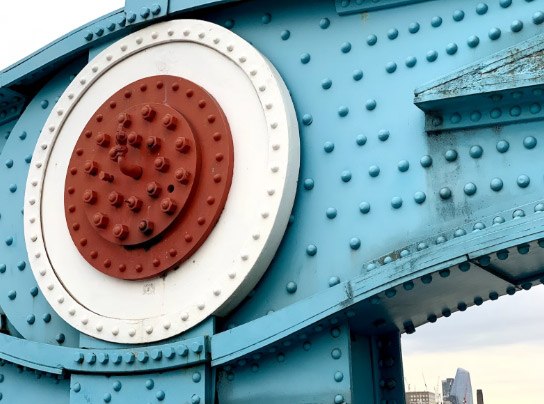

Bridges

Learn More

Our Longevity in the Industry

We started as a small forge shop in Ohio in 1884. Over the past century, we have grown to become one of the leading industrial forgers in the United States. We are proud of our history!

Why Work With Dyson Corp.?

Our Latest Blogs

Dyson Corp. Announces New Environmental Health & Safety Engineer for Engineering Team

We are thrilled to announce the newest addition to our Engineering Department – Juliet “Julie” Cooper, as the Environmental Health & Safety Engineer, reporting to Patrick Linehan, Director of Engineering. As we continue to grow

Dyson Corp. Announces New Systems Administrator for Finance/IT Team

Please join us in welcoming Jordan Brown to Dyson’s Finance/IT team. Jordan began working with us on Wednesday, September 20, 2023, as Systems Administrator, reporting to Mike Micale, Director of Finance. Jordan attended the University